JUKI AB-1351N-SAA AUTOMATIC 1 NEEDLE BELT LOOP ATTACHING MACHINE

Why Buy from Us?

- You are dealing with the official Juki Sewing Machine UK Importing and Distributing Network

- Your machine enquiry will be passed onto your local Juki dealer who will quote, setup, and install your new machines. As well as providing full after sales support and warranty

- Our centralised distribution warehouse supplies Juki machinery to all Juki Traders, providing the best possible service and local contact for your sewing requirements

Description / JUKI AB-1351N-SAA AUTOMATIC 1 NEEDLE BELT LOOP ATTACHING MACHINE

Juki AB-1351

Automatic 1-needle Belt-Loop Attaching Machine

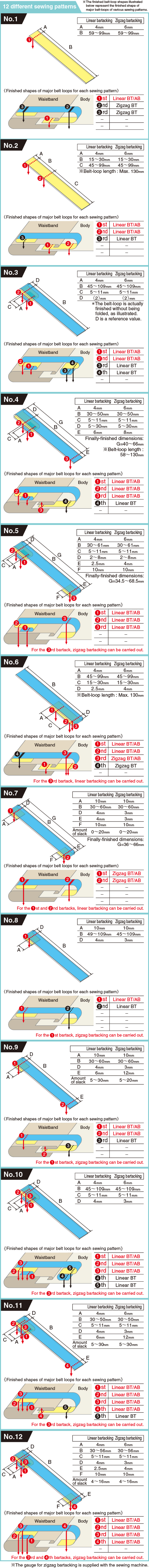

AB-1351 is the world's first belt-loop attaching machine with the ability to solely sew seven different belt-loop sewing patterns!

JUKI's unique flexible automatic belt-loop attaching machine!

Belt-loop folding mechanism which supports various belt-loop specifications (patent pending)

This is the world's first automatic belt-loop attaching machine which can be used for seven different belt-loop attaching processes. The main mechanisms have been computerized to develop a belt-loop attaching machine which sews diversified belt-loop styles.

Improved productivity

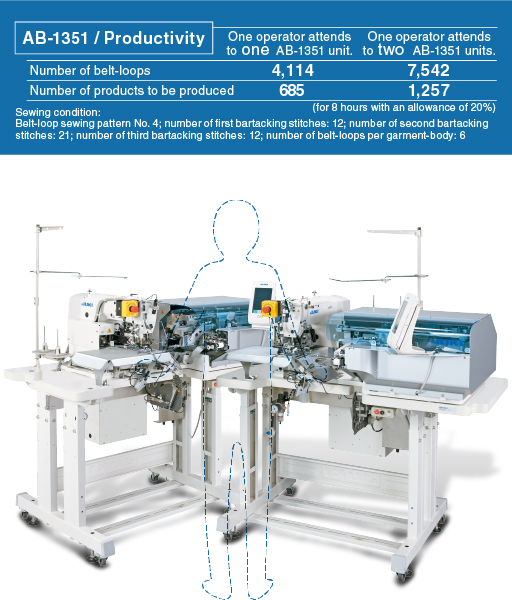

This machine not only reduces the time required for the belt-loop attaching process, but also achieves labor-saving, such as the elimination of the previous process (belt-loop cutting). Productivity can be dramatically increased when one operator attends to two AB-1351 units.

Productivity is dramatically increased when the operator attends to two AB-1351 units.

Two AB-1351 units can be operated by only one operator. In the case where two AB-1351 units are placed, as shown in the picture, the operator is able to operate them alternately to attach belt-loops on two different garment bodies, thereby substantially increasing productivity.

Quality production without relying on operator skill

This machine allows an inexperienced operator to sew various types of belt-loops. The operator only needs to place a garment body on the machine and press the switch. The belt-loop sewing shape and sewing size can be easily changed through the operation panel.

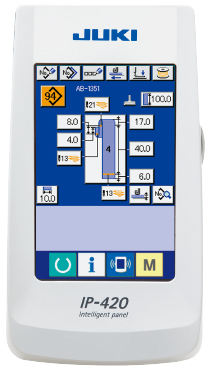

Belt-loop size adjustment and belt-loop specification changing have been digitalized

The AB-1351 has adopted, as its operation panel, the IP-420 which has a large color liquid crystal touch panel. With this operation panel, the operator can change the belt-loop shape or sewing pattern, set the belt-loop sewing position and carry out cycle sewing. When the belt-loop width is changed, the bartacking width can be automatically changed according to the percentage of change of the belt-loop width. Digitalization helps substantially reduce the time required for sewing data adjustment.

Quality improvement

JUKI's unique belt-loop feeding/folding mechanism helps achieve beautifully-attached consistent-quality belt-loops with constant sewing dimensions (amount of slack).

JUKI's unique belt-loop feeder unit

The belt-loop feeder unit incorporates JUKI's unique twin system. It is able to feed belt-loops with consistency even when a soft and elastic material is used. The belt-loop feeder unit is arranged in front of the main body of the sewing machine. This allows the operator to insert belt-loops from the front of the machine. In addition, the operator can visually check the belt-loop state whenever necessary, even during sewing.

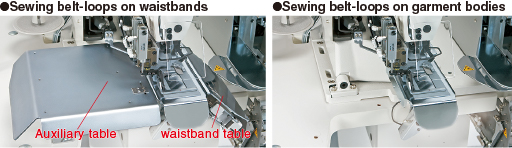

The machine can be used for two different sewing styles by installing / removing the sub-tables

The sewing machine can be used for two different sewing styles, i.e., for sewing belt-loops on waistbands (flat sewing) and for sewing belt-loops on garment bodies (tubular sewing), by installing / removing the sub-tables (auxiliary table and waistband table). The position of the start switch can also be changed. (The machine is provided with sub-tables as standard accessories.)

Technical Specification

| Model name | Juki AB-1351 |

|---|---|

| Machine head | LK-1961/ABH (Exclusive machine head based on the LK-1900A, Semi-dry-head) |

| Max. sewing speed | 2,500sti/min* |

| Lift of the work clamp foot | Max.14mm |

| Hook | Standard shuttle hook |

| Stored bartacking patterns (Stittches) | Linear bartacking (12, 15, 21, 28, 36, 41) / Zigzag bartacking (28, 36, 42, 56, 64) |

| Bartacking size | length-wise: 0~3.2mm (0"~1/8")(adjustable in increments of 0.1mm) cross-wise: 6~23mm (15/16"~57/64")(adjustable in increments of 0.1mm) |

| Number of bartacking patterns that can be input | Max. 200 patterns, (Max. 20,000 stitches in total patterns) |

| Number of belt-Loop sewing patterns | 99 patterns |

| Number of cycle sewing patterns | Number of programs: 20 (30 different patterns can be set within one program.) |

| Needle | DP × 17 #14, 135 × 17 #90 |

| Thread | Spun 80Nm (recommend), Filament 80Nm (80Nm=#50) |

| Belt-loop width | 8~20mm (5/16"~25/32") |

| Power requirement / Power consumption | Single-phase 220~240V / 280VA, 3-phase 200~220V / 250VA |

| Compressed air and air consumption | 0.5MPa (5kg/cm²), 10Nl/min |

| Total weight | 205.5kg |

| Dimensions | 1,200(W) × 850(D) × 1,210mm(H) |

| Height of the top face of the throat plate | Minimum: 930 mm (from the floor surface) |

| Needle thread breakage detecting device | Provided as standard (Sewing can be re-started in the case of thread breakage.) |

| Belt-loop multi-layered part detecting device | Provided as standard |

*sti/min is the abbreviation for “stitches per minute”

More Information

| Part No | JUKIAB1351NSAA |

|---|---|

| Weight (KG) | 0.100000 |

| Manufacturer | Juki |

Need a Spare Part?

We've got this covered!

You can find spare parts for all machinery on our parts website.