JUKI AC-172N-1790-SA1K BUTTONHOLE INDEXER LASER MARKER

Why Buy from Us?

- You are dealing with the official Juki Sewing Machine UK Importing and Distributing Network

- Your machine enquiry will be passed onto your local Juki dealer who will quote, setup, and install your new machines. As well as providing full after sales support and warranty

- Our centralised distribution warehouse supplies Juki machinery to all Juki Traders, providing the best possible service and local contact for your sewing requirements

Description / JUKI AC-172N-1790-SA1K BUTTONHOLE INDEXER LASER MARKER

Juki AC-172N-1790-SA1K

High-speed, Computer-controlled Buttonholing Indexer

(With Marking Light)

For a more sophisticated appearance, faster operation, and easier use!

The latest machine head reduces operating noise and improves the maintainability of the cloth-cutting knife.

Comes with a large color LCD touch panel to improve operability.

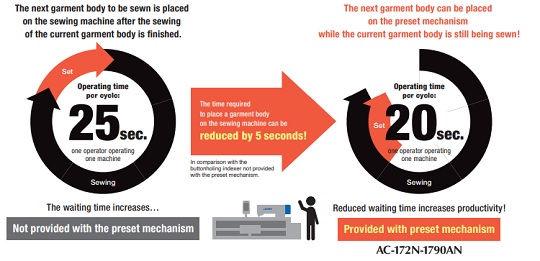

The preset mechanism helps increase productivity

Since the automatic buttonholing indexer carries out buttonholing successively, the operator conventionally has had waiting time while the sewing machine is in operation (for buttonholing). JUKI’s preset mechanism allows the operator to place the subsequent garment body to be sewn on the preset board while the sewing machine is still engaged in the sewing of the current garment body (so-called overlapping work). Consequently, the operator now can use his/her waiting time effectively during operation to achieve increased productivity.

Sub-clamp device to support the buttonholing of fabrics with vertical stripes

The sewing machine comes with a sub-clamp device that prevents material slippage during transport from the preset mechanism to the sewing machine. The independent sub-clamp device of the carriage unit on the machine head clamps the material to keep it from slipping out of position. This function promises reliable delivery operation and consistent seam quality even when sewing vertical-striped fabrics. The machine is also equipped with a function to eliminate false starts by detecting whether or not a material is present.

A large color LCD touch panel IP-420 for touch operation

The larger screen of the new color LCD touch panel displays sewing data such as the stitch shape and stitch number. The input function on the operation panel enhances ease of use by allowing the operator to input and edit sewing data while watching the area around the needle entry points. The operation panel is equipped with USB and CompactFlash ports for easier software upgrades and data-sharing with other devices.

A single buttonholing indexer for both men’s and ladies’ shirts

The sewing mode can be easily switched between men’s dress shirts and ladies’ blouses on the operation panel. Sewing specifications (buttonhole size, buttonhole interval, etc.) can also be quickly and easily changed with a few touches of the panel interface. Buttonholes can be sewn from the top when sewing ladies’ garment bodies, just as they are with men’s. The machine can also space button-holes at different intervals on a garment, as required.

High-performance indexer mechanism

A stepping motor controls material feed amounts in increments of 0.1 mm to feed materials with both consistency and accuracy. The machine is able to sew 1 to 20 buttonholes and stores 20 different stitching patterns in its memory. The sewing machine is provided as standard with a facility that moves the carriage unit synchronously with the operation of the sewing machine during sewing, thereby enabling accurate and unfailing feed of the material while preventing material slack.

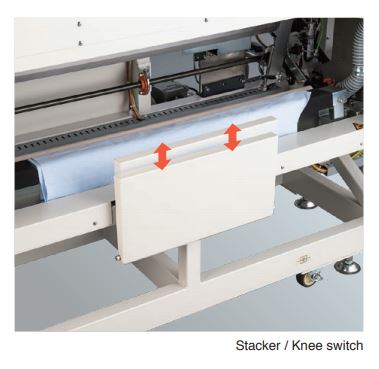

Space-saving type stacker built into the main body of the sewing machine

The stacker clamps the buttonholed garment body and automatically stacks it without fail. This operation increases productivity by improving the efficiency of the material taking/stacking by the operator.

Knee switch and hand switch are also provided

The operator can use the knee switch to turn ON the machine start switch while holding a garment body with both hands. This feature increases the stability of material placement and shortens the time required to complete it. The height of the knee switch is adjustable. If the operator turns ON the machine start switch with a material placed on the preset mechanism, the sub-clamp device automatically carries the next material to the sewing position after the current material is buttonholed. This function improves productivity by allowing the operator to run two or more sewing machines or carry out other tasks while buttonholing is underway.

Equipped with an LED light to illuminate the needle entry area

The LED light is equipped as standard under the arm jaw. The LED light lights up automatically whenever the sewing machine power is turned ON. This LED light provides a comfortable work environment to help the operator easily thread the needle and check the stitches.

Technical Specification

| Model name | Juki AC-172N-1790-SA1K |

|---|---|

| Max. sewing speed | 4,200 sti/min (normal:3,600 sti/min)* |

| Sewing dimension | Standard : Width 4mm x length 25mm (Max. Width 6mm x length 120mm by repiacing parts) |

| Cloth trimming length | 6.4~19.1mm (1/4~3/4 inch) |

| Lift of the work clamp foot | Max.14mm |

| Needle | DPx5 #11J~#14J (Needle installed at the time of delivery #11J) |

| Feed system | Stepping motor |

| Feed direction | Right (for men's garments) or left (for ladies' garments) |

| Unit of feed amount | 0.1mm |

| Number of patterns that can be input | 20 patterns |

| Number of buttonholes | 1~20 pcs. |

| Power requirement | 3-phase 200~240V, Single-phase 220~240V |

| Power consumption | 800VA |

| Compressed air and air consumption | 0.5MPa (5kg/cm²) 240Nl/min |

| Dimensions | 1,910(W) x 850(D)x920mm(H) (Up to the preset table surface) |

| Total weight | 300kg |

| Presetting device | Provided as standard |

| Stacker | Provided as standard |

| Lubricating oil | JUKI New Defrix Oil No.1 |

| Marking Light | Supplied |

| Cloth Edge Sensor | - |

| Support Clamp | - |

*sti/min is the abbreviation for “stitches per minute”

More Information

| Part No | JUKIAC172N1790SA1K |

|---|---|

| Weight (KG) | 0.100000 |

| Manufacturer | Juki |

Need a Spare Part?

We've got this covered!

You can find spare parts for all machinery on our parts website.