JUKI AMB-289A HIGH SPEED BUTTON NECK WRAPPING MACHINE

Why Buy from Us?

- You are dealing with the official Juki Sewing Machine UK Importing and Distributing Network

- Your machine enquiry will be passed onto your local Juki dealer who will quote, setup, and install your new machines. As well as providing full after sales support and warranty

- Our centralised distribution warehouse supplies Juki machinery to all Juki Traders, providing the best possible service and local contact for your sewing requirements

Description / JUKI AMB-289A HIGH SPEED BUTTON NECK WRAPPING MACHINE

Juki AMB-289A

Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine

The machine comes with an exclusive active-tension system ideal for the careful sewing of beautiful seams.

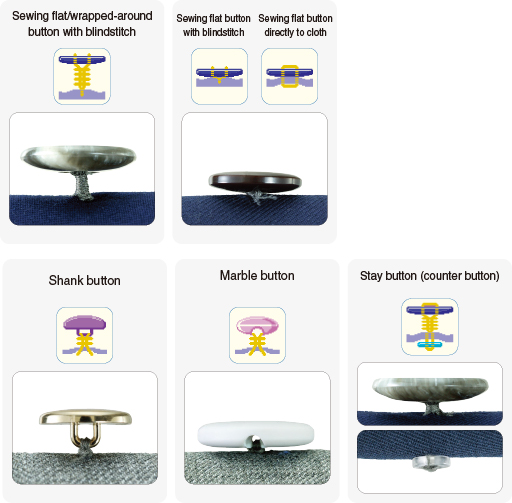

This single machine can also sew flat buttons, shank buttons, marble buttons and stay buttons (counter buttons).

This single machine can also sew flat buttons, shank buttons, marble buttons and stay buttons (counter buttons)

The stay button (counter button) sewing capability is a vital addition to the impressive application range of the AMB-289.

Sewing methods and sewing shapes can be easily reset on the operation panel.

In combination with the independent-drive needle-throwing method, the adoption of the Y-feed on the body side and X-Y feed on the button-sewing side enables the AMB-289 to sew patterns with variable numbers of buttonholes (such as four-holed front buttons and two-holed stay buttons).

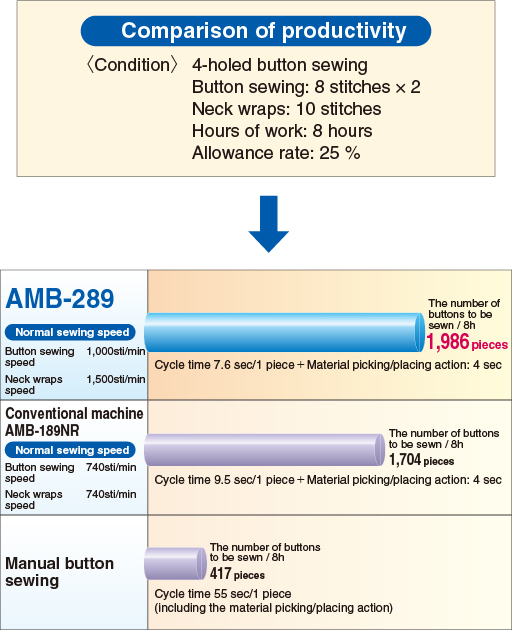

The cycle time has been reduced to bolster productivity

The sewing speed has been enhanced to dramatically increase productivity.

As compared with manual button sewing, the AMB-289 achieves productivity as high as 5 times.

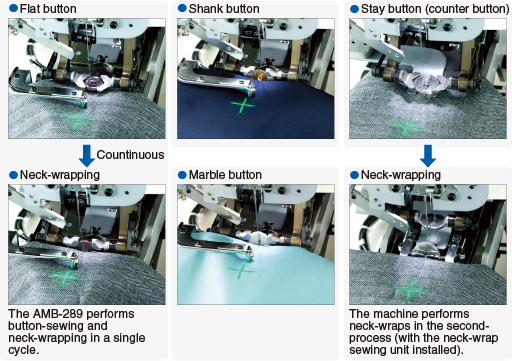

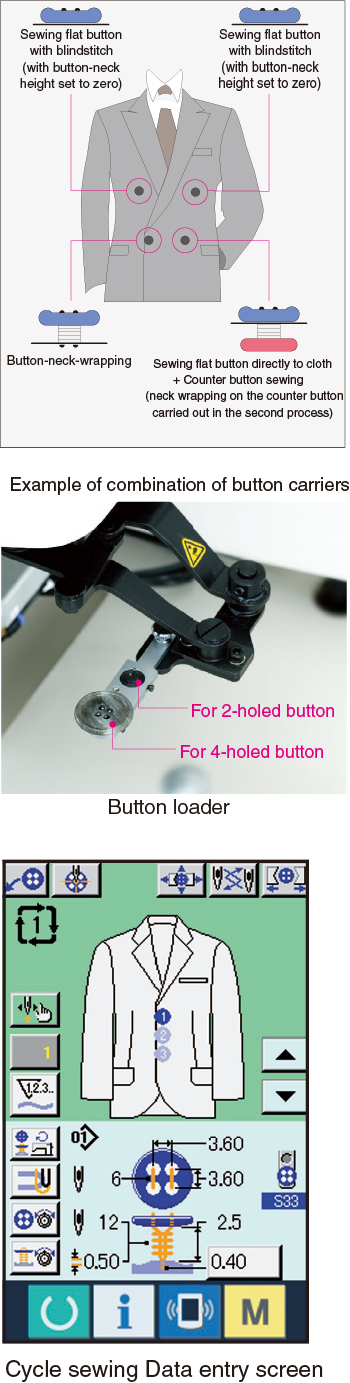

Cycle sewing

The machine sews buttons on a double-breast suit, a garment that requires the sewing of different types of buttons, in a continuous manner.

Cycle sewing data can be set/edited with the sewing item graphically displayed on the operation panel (the number of buttons, button sewing locations, and sewing order of buttons).

The button loader can feed two types of buttons in a single sewing cycle.

The color panel IP-420D provides excellent operability

The operation panel is a touch-sensitive type LCD. The clear graphical displays make it much easier for the operator to set or modify sewing data.

A CompactFlash™ card can be used to store and transfer sewing data. This makes it possible for sewing machines at one or more factories to share data. In addition to the CompactFlash TM, the machine is provided as standard with a USB connector. As a result, the use of a USB flash drive or card reader enables the storage and transmission of sewing data by means of various kinds of media (such as a floppy disk, SmartMedia, CompactFlash and SD card) to enable sewing using the same sewing data among sewing machines in a plant or among subcontract plants.

The AMB-289 promises upgraded-quality neck-wrapping

The AMB-289 finishes four-holed buttons with a hand-stitched appearance (V-shape stitching) by fixing the tucking position at a preset location. This results in the sewing of a neat seam on the wrong side of the garment and neck-wrap knots at a single location. Seam quality is further enhanced as a result.

The neck-wrap data can be finely adjusted via the entry screen of the operation panel to enhance the sewing quality. The distribution of neck wraps on the upper and lower parts of the button neck, a crucial point in determining the quality of neck-wrapping, can be adjusted to prevent buttons and button necks from becoming unstable and tilting.

The neck-wrapping height can be adjusted by up to 10mm.

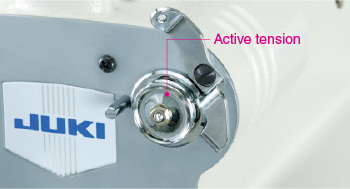

Exclusive active tension (electronic thread tension control system)

The exclusive active tension system for AMB289 further improves responsiveness and allows delicate tension setting when the user changes fabrics.

Thread tensions for button sewing and neck wrapping can be separately set on the operation panel.

The machine stores sewing conditions in memory on a pattern-by-pattern basis. Required sewing conditions can be exactly reproduced for every pattern.

Superb functions for improving seam quality

The remaining length of needle thread can be adjusted according to the type of material or thread to be used. It effectively prevents thread from slipping off the material at the start of sewing.

The AMB-289 does not require the use of exclusive thread intended for button sewing. General-purpose cotton threads and spun threads are both applicable, depending on the type of material.

A full range of thread counts from 500~170dtex (#60~#30CA) can be applied. This ensures use for diverse processes.

The thread-trimming position is set to reduce the remaining length of thread on the material to a minimum.

The machine incorporates a thread-fray prevention function that ensures the tying of strong and reliable knots at the last stitch.

The number of stay stitches, which increases strength of button sewing stitches, can be set on the operation panel within the range of 0 and 3 stitches.

The tucking depth is increased to 5mm to ensure a consistent tucking depth in soft materials such as knits.

The feed accuracies are high as 0.05mm (some points are 0.1mm). This promises an accurate needle entry position and tucking depth.

The machine comes with new functions to improve workability

Dramatically reduced oil stains

As the machine requires no lubrication, oil spatters and all other lubrication-related troubles are eliminated. Sewn garments have dramatically fewer oil stains as a result.

* Periodical greasing is required for some of the mechanical structures.

Dramatically reduced vibration and noise

The adoption of the needle-throwing mechanism dramatically reduces the vibration and noise usually produced during the neck-wrapping procedure.

The machine is provided as standard with a button loader

The machine is provided as standard with a button feeder that lets the operator place the next buttons to be sewn during overlapping-style work.

The button-delivery position between the button loader and button chuck can be easily adjusted on the operation panel. No tools are required.

LED now adopted

The AMB-289 is provided as standard with an LED-type handy light and marking light. The sewing area is now brighter and more viewable than it would be under the incandescent light of a conventional machine. LED light also offer the advantage of a longer service life. The machine is optionally provided with a marking light for sewing flat buttons directly to cloth.

Convenient hand pulley

The hand pulley is mounted on the top of head. This makes it easy to check the needle entry point.

The button loader gauge for the conventional model can also be used with the AMB-289

The set pins and four-holed and two-holed button carriers used with the AMB-189NR (the conventional model provided with a button loader) can also be used with the AMB-289.

* The AMB-289 requires dedicated set pins for shank buttons, marble buttons, and metallic buttons (optional).

Safety design

The safety-first design makes it impossible to start the machine without buttons set on the button chuck.

If the machine head tilts while the power ON, the safety switch automatically shuts down the machine even when the pedal or knee switch is pressed.

Applicable button requirements

Technical Specification

| Model name | Juki AMB-289 |

|---|---|

| Stitch type | Single-thread chainstitch |

| Max. sewing speed | 1,800sti/min* (neck-wrapping), 1,200sti/min* (button sewing) |

| Normal sewing speed | 1,500sti/min* (neck-wrapping), 1,000sti/min* (button sewing) |

| Application | Sewing of various button types (buttons to be sewn by machine) |

| Button size | Sewing button without neck-wrapping : φ8~φ38mm Sewing button with neck-wrapping : φ8~φ32mm Counter button : φ8~φ25mm |

| Display screen for setting basic shape-setting | Distance between buttonholes: 1.5~6.0mm (in increments of 0.1mm) Height of neck-wrap: 0, 1.5~10.0mm (in increments of 0.1mm) Number of cross-over stitches: 2~64 (in increments of 2) |

| Needle | ORGAN SM×332EXTLG-NY (standard needle), (at the time of delivery #14) #12~#18 |

| Thread | SPUN / Cotton thread 500~170dtex (#60~#30CA) |

| Thread take-up | Needle thread take-up |

| Needle bar stroke | 60.0mm |

| Needle throwing system | drived by Stepping motor |

| Feed system | drived by Stepping motor |

| Auto-lifter | drived by Stepping motor |

| Cloth feeding system | drived by Pneumatic |

| Thread trimming system | drived by Pneumatic |

| Thread tension adjustment | Active tension (Exclusive electronic thread tension control system) |

| Number of data that can be input | Max. 99 patterns |

| Number of cycle stitch patterns | The number of registered patterns: 20 (30 patterns for one cycle) |

| Operation panel | Color LCD touch panel: IP-420D |

| Button loader | Provided as standard |

| Product count | Provided as standard (up/down system) |

| Lubrication | No lubrication * Periodic greasing is required. |

| Power requirement and power consumption | Single-phase 200~240V, 3-phase 200~240V/400VA |

| Compressed air and air consumption | 0.5MPa(5kgf/cm²), 11dm³/min |

| Dimensions | 600mm(W)×600mm(D)×400mm(H) |

| Weight | Machine head: 65kg, Control box: 13kg |

*"sti/min" stands for "Stitches per Minute."

More Information

| Part No | JUKIAMB289A |

|---|---|

| Weight (KG) | 0.005000 |

| Manufacturer | Juki |

Need a Spare Part?

We've got this covered!

You can find spare parts for all machinery on our parts website.