JUKI AMS-210EN-HL1306-SZ/5000D PATTERN SEWING MACHINE

Why Buy from Us?

- You are dealing with the official Juki Sewing Machine UK Importing and Distributing Network

- Your machine enquiry will be passed onto your local Juki dealer who will quote, setup, and install your new machines. As well as providing full after sales support and warranty

- Our centralised distribution warehouse supplies Juki machinery to all Juki Traders, providing the best possible service and local contact for your sewing requirements

Description / JUKI AMS-210EN-HL1306-SZ/5000D PATTERN SEWING MACHINE

Juki AMS-210EN-HL1306-SZ/5000D

Computer-controlled Cycle Machine with Input Function (130mm x 60mm Sewing Area)

New technologies have helped the AMS Series increase “productivity,” achieve ”energy conservation” in consideration of the global environment, and further improve “quality.”

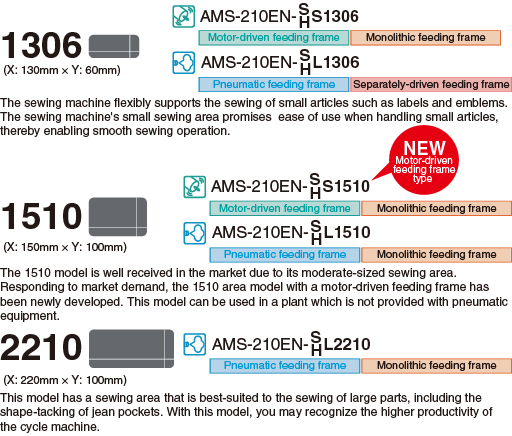

The AMS-210EN Series comes in three different models which differ in sewing area

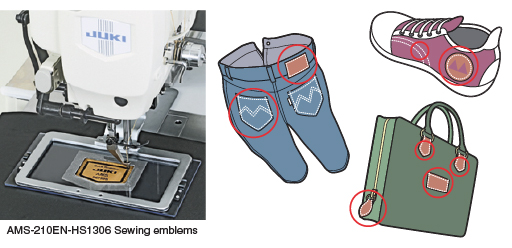

The sewing machine flexibly supports the sewing of amall articles such as labels and emblems. The sewing machine's small sewing area promises ease of use when handling small articles, thereby enabling smooth sewing operations.

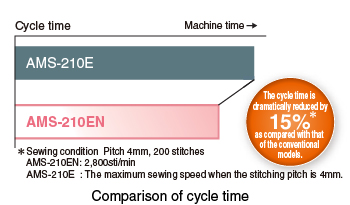

Cycle time is shortened

The sewing machine has achieved the industry's highest sewing speed of 2,800sti/min. The maximum sewing speed is reached by the 2nd stitch from the beginning of sewing. Since the sewing machine maintains its highest sewing speed immediately before the end of sewing and instantaneously decreases its speed, cycle time can be substantially decreased.

JUKI's unique stepping-motor controlled thread trimming mechanism is adopted to enable speedy and consistent thread trimming performance.

The machine demonstrates enhanced responsiveness due to the adoption of a main-shaft direct-drive system.

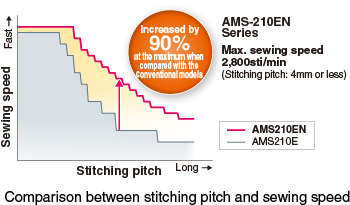

The maximum sewing speed per stitching-pitch (stitch length) is increased

Sewing at the maximum sewing speed of 2,800sti/min is possible up to stitching pitch of 4mm for the AMS-210EN (the highest sewing speed and stitching pitch in the industrial sewing machine industry). Even for the larger pitches, the sewing speed is increased by 90% for the AMS-210EN and by 60% for the AMS-221EN at the maximum when compared with the conventional models, thereby reducing the cycle time.

* The sewing speed is automatically controlled according to the stitching pitch.

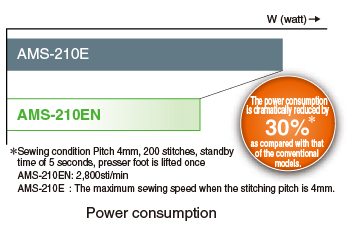

Power consumption is substantially decreased

The AMS Series are an economically-efficient model which has been designed to reduce power consumption.

The AMS-210EN is an economically-efficient model which has been designed to reduce power consumption. The sewing machine has adopted a direct-drive system by means of a compact AC servomotor that is excellent in energy transmission to drive the main shaft, and has adopted an encoder-control system which drives the stepping motor with a minimum of power in accordance with the material thickness and stitch length to control the X-Y drive mechanism. Power consumption of the new AMS Series is reduced by 30% when compared with JUKI's conventional AMS-210E.

Improvement of seam quality

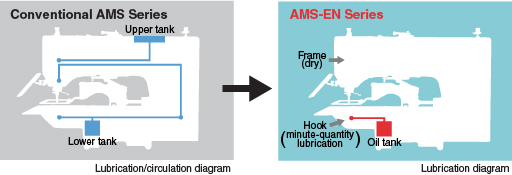

The frame (needle bar unit and thread take-up unit) is lubricated with grease, and the hook is fed with a minute quantity of oil from the oil tank. JUKI's advanced dry technology, which is utilized in a number of our sewing machine models, protects your products from being stained with oil.

Semi-dry head

The frame (needle bar unit and thread take-up unit) is lubricated with grease, and the hook is fed with a minute quantity of oil from the oil tank. JUKI's advanced dry technology, which is utilized in a number of our sewing machine models, protects your products from being stained with oil.

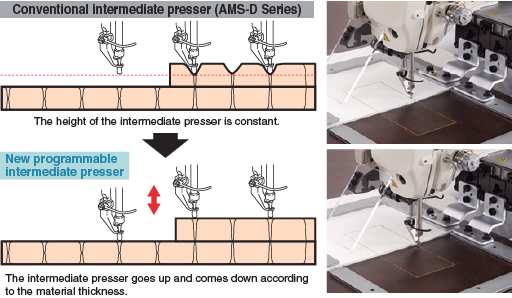

Programmable intermediate presser

To support the sewing of multi-layered parts of materials, the lower dead point height of the intermediate presser can be changed steplessly during sewing (standard: 0~3.5mm; maximum: 0~7.0mm). The intermediate presser will now be able to clamp the material without fail, thereby preventing troubles in sewing, such as stitch skipping and thread breakage. Furthermore, flaws on the sewing product are prevented by maintaining the intermediate height as desired according to the material thickness. (The intermediate presser stroke is adjustable between 0 and 10mm.)

Two different types of feeding frames

The feeding frame comes in two different types; the monolithic feeding frame and the separately-driven feeding frame. The separately-driven feeding frame enables easy placement of the sewing material on the machine since its right and left frame parts can be operated separately. Both the amount of lift and the ascending/descending speed of the feeding frame can be adjusted differently for the right and left parts of the frame.

Double-stepped stroke feeding frame

The feeding frame can be lowered in two steps. It is very convenient for finely positioning the material on the sewing machine. The stopping height of the feeding frame can be set as desired with ease.

Active tension

Market-proven active tension has been introduced to the needle thread tension controller. With the active tension, pinpoint changes in the needle thread tension during sewing are enabled. The needle thread tension, therefore, can be set in conjunction with the material thickness and can be corrected according to the direction of sewing on a stitch-by-stitch basis through the operation panel. Since the needle thread tension is reproducible, supporting a broader range of sewing conditions, the time required for setup changing upon process changeover can be reduced.

The machine supports a broader range of materials and various sewing specifications

The machine can be used for free pattern stitching, parts sewing, reinforcement stitching, etc.

Examples of applications include the attaching of labels, emblems and name labels, the attaching of Velcro, various shape-tacking, and special bartacking.

Operation panel provided with programmable functions IP-420 (provided as standard)

The large-sized liquid crystal touch panel, which has been developed to ensure ease of operation, dramatically increases efficiency in edit work.

The IP-420 touch panel offers market-proven ease of operation. It is provided with a wide screen and programmable functions. Data can be input/edited while visually checking the needle movement.

The color LCD unit displays sewing data such as stitch shape, needle thread tension, enlargement/reduction ratio, sewing speed and the number of stitches at a glance. The IP-420 is provided as standard with 14 different display languages.

Key-lock customization function

The key-lock state can be set as desired. It is therefore possible to hide items which should not be handled by the operators.

Simplified operation mode

Simplification of set items and screen transition of the IP-420 increases ease of use and helps reduce operator fatigue.

The memory storage capability of the main body of the sewing machine has been dramatically enhanced

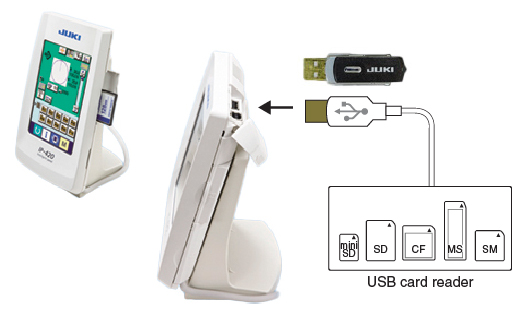

Now the USB-ready main body of the sewing machine uses many different kinds of media

Sewing data created with the IP-420 can be stored in the memory of the main body of the sewing machine. The memory storage capacity is 500,000 stitches and 999 patterns (max. 50,000 stitches per pattern) at the maximum. In addition to the CompactFlash 33 card, the main body of the sewing machine is provided as standard with a USB connector. Now, data can be input/output to/from various kinds of media (FD (floppy disks), SM (SmartMedia), CF (CompactFlash), SD (Secure Digital Card) etc.) by means of a USB thumb device and a card reader. The maximum number of stitches that can be stored in the memory for each medium is approximately 50,000,000.

Subclass - Technical Specification

| Model name | Juki AMS-210EN-HL-1306 |

|---|---|

| Sewing area | X : 130mm × Y : 60mm |

| Feeding frame type | Separately-driven feeding frame Pneumatic feeding frame (lifting amount: 30mm) |

| Application | Medium- to heavy-weight |

| Needle | DP×17(#18) |

| Thread | #50~#2 |

| Compressed air / Air consumption | 0.35~0.4(max. 0.55)MPa, 1.8dm³/min(ANR) |

| Dimensions / Weight | 1,200mm(W)×710mm(D)×1,200mm(H) (thread stand is not included), Machine head: 69kg, Control box: 16.5kg |

Specification common to all models

| Max. sewing speed | 2,800sti/min* |

|---|---|

| Stitch length | 0.1~12.7mm (0.05mm step) |

| Needle bar stroke | 41.2mm |

| Lift / Stroke of the intermediate presser | Lifting amount: 20mm / Stroke: Standard 4mm (0~10mm) |

| Variable lower position of the intermediate presser | Standard 0~3.5mm (max. 0~7.0mm) |

| Needle thread tension | Active tension (electronic thread tension control mechanism) |

| Hook | Double-capacity shuttle hook |

| Storage of pattern data in the memory | Main-body memory: Max. 500,000 stitches, 999 patterns (max. 50,000 stitches / pattern) External media: Max. 50,000,000 stitches, 999 patterns (max. 50,000 stitches / pattern) |

| Enlarging / Reducing facility | 1~400% (0.1% step), Pattern enlargement / reduction can be done by increasing / decreasing either stitch length or the number of stitches |

| Bobbin thread / Product counter | Up / Down system (0~9,999) |

| Lubrication | Semi-dry / hook section: minute-quantity lubrication (tank system) |

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) |

| Sewing machine motor | AC servomotor 550W (direct-drive system) |

| Power requirement / Power consumption | Single-phase, 3-phase 200~240V/450VA |

*Stitch length is 4mm or less for the AMS-210EN.

*sti/min is the abbreviation for “stitches per minute”

More Information

| Part No | JUKIAMS210ENHL1306S |

|---|---|

| Weight (KG) | 92.000000 |

| Manufacturer | Juki |

Need a Spare Part?

We've got this covered!

You can find spare parts for all machinery on our parts website.